Variable Frequency Drives VFD:

VFD is a type of ASD (adjustable speed drives) that is used to control AC motors.

AC motors can be of synchronous or asynchronous type, depending upon the use. However, asynchronous (Induction) motors due to there cheap cost are most widely used.

Whether, the motor is synchronous or asynchronous, the working principles of VFDs remain valid for both scenarios.

With proper use of VFD speed as well as power consumptions of AC motors may be controlled. From the fundamental of electrical machines we know that ;

energy consumption α (1/speed)^3

Working Principle:

Following are the fundamental principles of any AC drive;

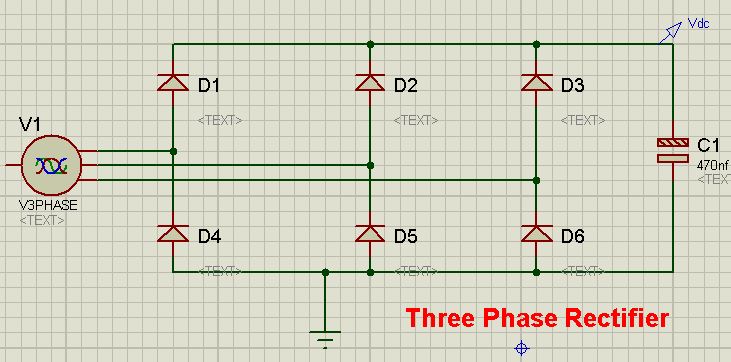

- Line AC (Three Phase or Single) is converted to DC using RECTIFIER.

- DC voltage (Vdc) from the rectifier is then converted to modified AC Voltage (Vac) using INVERTER.

- FIRING CIRCUITRY is used to control the output voltages and frequency of the inverter.

- Output Voltage = (duty cycle)*Vdc ; where (duty cycle)='Ton'/('Ton' + 'Toff').

- Speed of AC motor is directly related to Frequency of AC voltage.

- Voltage / Frequency ratio is directly related to torque, for constant load operations it is highly recommended that it should remain constant. If this ratio gets higher than it might break the mechanical coupling or if it may get lower it would be harmful to motor's windings.

Rectifier:

Rectifier shown below is used to provide the DC voltage for the inverter, in the case if you are designing a transformer less system. Diode current rating should be 1.25 times greater then the maximum current rating of load. Fuses and other protection devices (like MOVs) might be use. Caution: High Voltage!Take proper precautions.

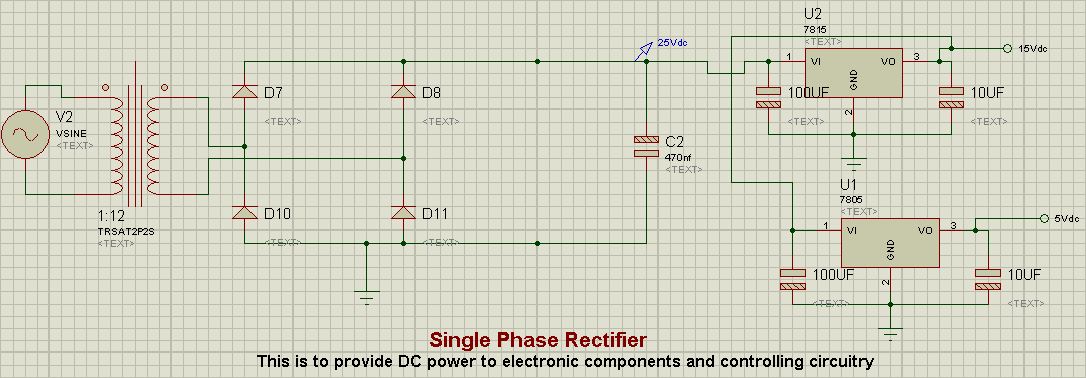

Following circuitry might be suitable to energize controller and firing circuitry of inverter. If you don't want to feed inverter with high voltages then you might step down line voltages first then use step up transformer at the output :)